Summer means hitting the local car shows and cruising the main drag in your classic car or hot rod.

Classic-car owners sometimes ask if they need to add a leaded fuel substitute to their gasoline. For decades, Tetraethyllead was added to gasoline to reduce engine knock and help prevent valve-seat recession. Once lead’s negative effects became clear, regulators began phasing it out in the 1970s. But, what about classic-car engines from the 1950s and 1960s that were built with leaded gasoline in mind? Do they require a lead substitute?

Why lead was added to gasoline

First, let’s look at the primary reasons lead was added to gasoline in the first place.

- Increase octane to help reduce engine knock

- Protect against valve-seat recession

Protects against pre-ignition

Gasoline’s octane rating indicates its ability to withstand compression before igniting. During operation, the piston travels up the cylinder and compresses the fuel/air mixture in preparation for ignition. Compression heats the mixture to help it ignite more easily and burn more completely. Compressing the fuel/air also maximizes the volume packed into the cylinder, which boosts power and efficiency. All other factors being equal, that’s why engines with higher compression ratios typically put out more power.

If the compressed, heated gasoline reaches its ignition point too soon, however, it will auto-ignite prior to the spark plug firing. This disrupts engine timing, reduces power and can damage the engine. It’s important to use gasoline with the correct octane rating for your engine to avoid pre-ignition. Higher-compression engines require higher-octane gas.

Chemists discovered in the 1920s that Tetraethyllead added to gasoline was a cost-effective solution to pre-ignition and helped engines run better.

Protects against valve recession

Lead also emerged as an effective way to protect against valve-seat recession, which can occur under high-rpm, high-heat, high-load conditions. As the intensely hot exhaust valve hammers against the valve seat thousands of times per minute, the two components can momentarily fuse together in a process called “microwelding.” Once the valve opens, the microweld tears apart. Multiply this by thousands of times and the valve seat deteriorates until the valve no longer seats properly. This leads to compression and power loss, in addition to catastrophic failure if the valve breaks off.

Hardened valve seats introduced

By the mid-1970s, we’d become aware of lead’s negative effects on human health, the environment and automotive catalytic converters. As regulators began working to eliminate lead from gasoline (and other products), engineers began designing engines with unleaded gas in mind. To combat microwelding, they used hardened valve seats, which are more resilient to valve recession.

But, what about classic-car engines built prior to widespread use of hardened valve seats?

Lead substitutes offer an answer

To solve the problem, many enthusiasts add a lead substitute to their gasoline. Lead substitutes contain chemicals that form a sacrificial layer to inhibit microwelds and protect valve seats.

Do I need a leaded fuel substitute?

If you’ve rebuilt the motor or done work to the cylinder heads, it’s likely that hardened valve seats were used, which means a lead substitute isn’t necessary.

However, if the engine is original and uses stock valve seats (i.e. non-hardened), we recommend using a lead substitute for added protection. This is especially true if your operating conditions border on “severe” territory. For a cast-iron, high compression-ratio engine of that era, it doesn’t take much to wind up the rpm, turn up the heat and operate in conditions that promote valve-seat recession. Using a lead substitute offers peace of mind that your classic is protected.

AMSOIL DOMINATOR® Octane Boost = excellent leaded fuel substitute

Improves Performance in all Two- and Four-Stroke Gasoline-Fueled Engines

AMSOIL DOMINATOR® Octane Boost (AOB) significantly increases engine response and power in all two- and four-stroke gasoline-fueled engines by increasing octane up to four numbers. Just one treatment reduces engine knock, improves ignition and helps fuel burn cleaner. DOMINATOR Octane Boost is the recommended octane boost for all high-performance off-road and racing applications. Most users find one 12-ounce bottle of DOMINATOR Octane Boost for 15 gallons of gasoline provides the ideal performance increase. DOMINATOR Octane Boost is also excellent as a lead substitute at the same treat rates in collector automobiles, older off-road equipment and pleasure vehicles.

DOMINATOR Octane Boost works great as a lead substitute in classic cars. It contains MMT (Methylcyclopentadienyl manganese tricarbonyl), which is a metallic additive that creates a sacrificial barrier on valve seats to help prevent recession and keep your engine running strong.

Not only that, as its name suggests, it boosts octane up to four numbers, which is just as important in older high-compression engines that were made with leaded gas in mind. It increases engine response and power in all two- and four-stroke gasoline-fueled engines. Just one treatment reduces engine knock, improves ignition and helps fuel burn cleaner.

It’s another product in your arsenal when you talk to classic car owners this summer.

Engineered for classic vehicles

High-zinc formula

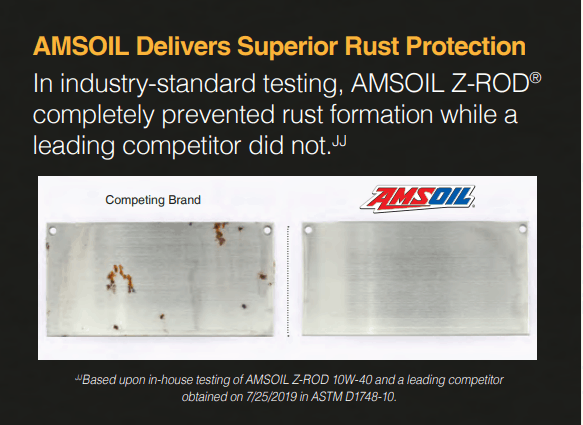

Protects against rust during storage

Do Classic-Car Engines Need High-Zinc Oil?

This is one of the most common questions we receive regarding older engines in classic cars and hot rods. For the best protection, we recommend using a high-zinc oil, such as Z-ROD® Synthetic Motor Oil, in these engines.

What is high-zinc motor oil?

Zinc dialkyldithiophosphate (ZDDP) is the most common zinc-based additive and is used primarily as an antiwear agent to help prevent engine wear. It also provides corrosion and oxidation protection.

However, because the zinc and phosphorus found in ZDDP can negatively affect catalytic converters, it has been phased out of motor oil formulations in recent years.

Reducing ZDDP has drawbacks. Older vehicles with flat-tappet camshafts and high-tension valve springs or other modifications that create high contact pressures can suffer premature wear due to reduced ZDDP levels.

For the best protection, use high-zinc and high phosphorus motor oil to offer extra protection for flat tappet cams, lifters and other components.

How do ZDDP additives work?

ZDDP anti-wear additives are heat-activated, meaning they provide wear protection in areas of increased friction.

As temperatures rise and surfaces come closer together, ZDDP decomposes and the resulting chemistry protects critical metal surfaces.

When parts move during operation, any sliding or rolling motion takes place on top of or within the ZDDP antiwear film, which reduces metal-to-metal contact. This helps prevent wear so enthusiasts can keep their classic cars or hot rods running great for years.

Flat-tappet lifters can wear down sooner compared to roller lifters due to increased pressure. Z-ROD Synthetic Motor Oil contains added ZDDP to protect lifters against wear and help maintain power.

AMSOIL Products

Become a Preferred Customer or Catalog Customer

In about five minutes, we can set you up with whichever account gives you the greatest benefits.

Whatever your comments, suggestions or questions,

we welcome you to Contact Us!

The best ways to reach us are via our Contact Us page, or by calling us toll free at

1-800-581-5823 between 8 am and 9 pm CST Monday through Saturday.

You are welcome to 'Like" us on Facebook where we share news about our AMSOIL products and customers.

Please follow us on our LinkedIn Company Page for news as well.

If you're on Twitter, you'll find us at @vaughn_inc

You're welcome to follow our AMSOIL product news bites there as well.

Remember, the best way for you to reach us is via the contact us page on this website or by calling toll free 1-800-581-5823 between 8 am and 9 pm CST Monday through Saturday.

Whatever your interest we welcome your inquiry!